Welcome to TFL Door

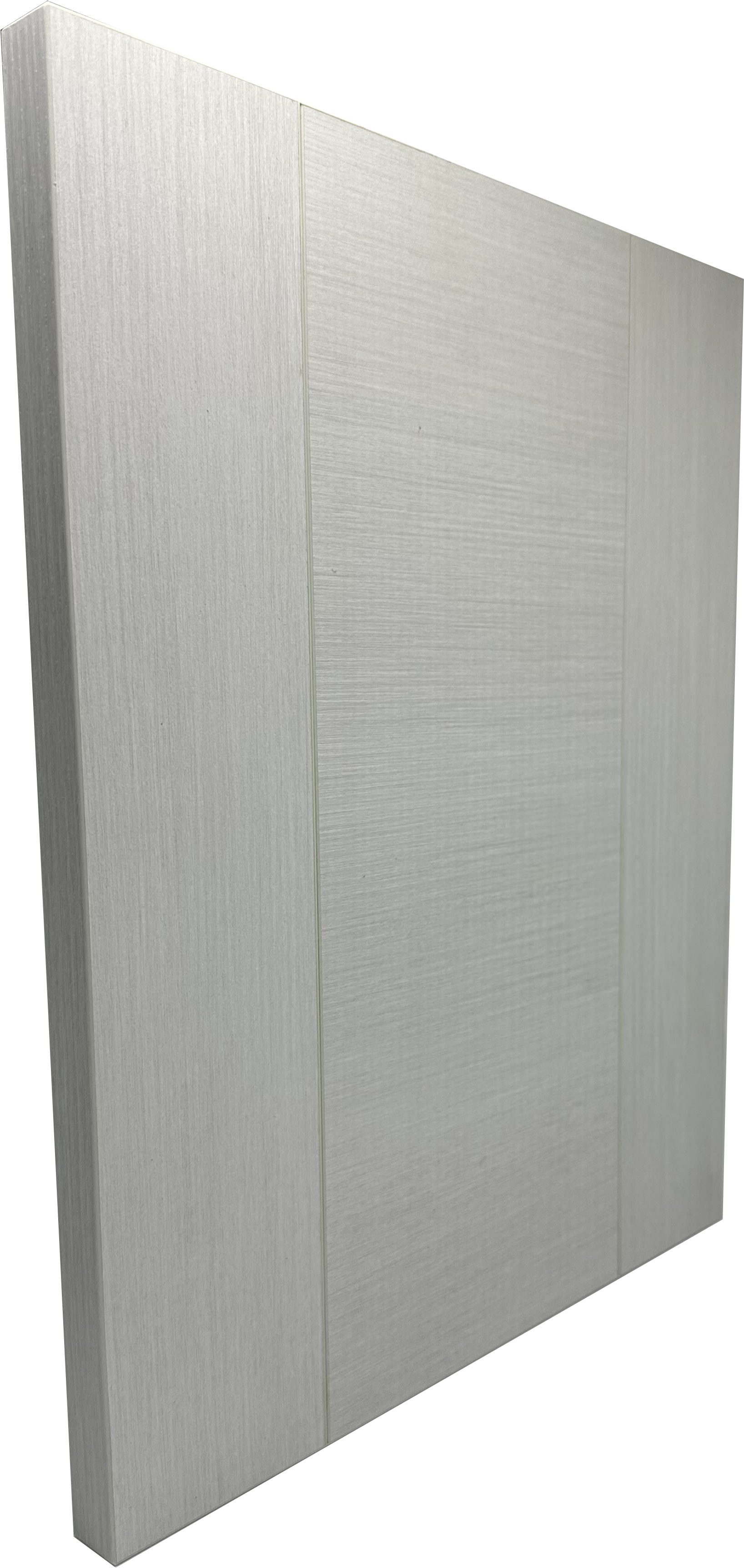

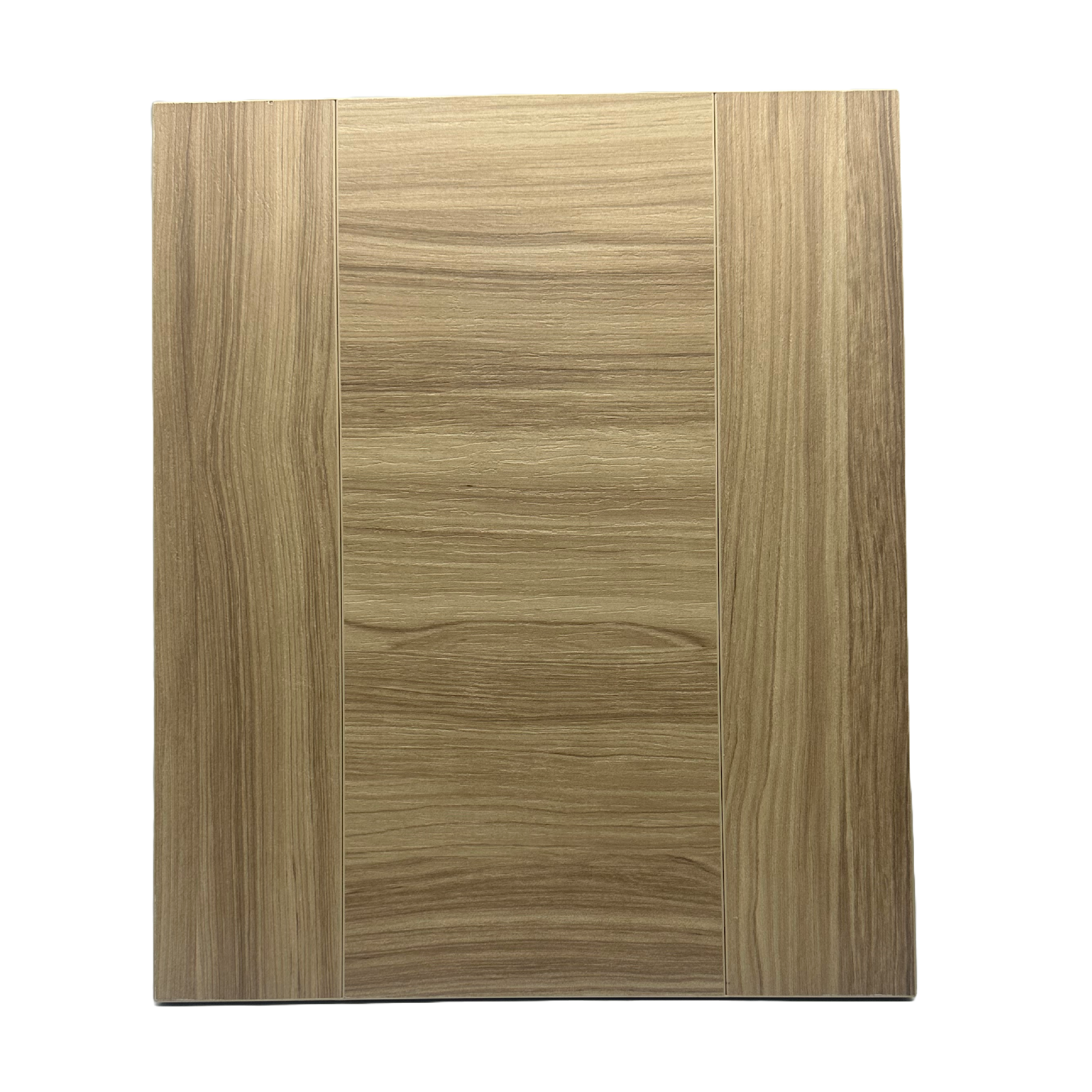

At TFL Doors, we craft cabinet doors that combine cutting-edge materials with unmatched craftsmanship. Specializing in Thermally Fused Laminate (TFL), our doors offer a perfect blend of durability, style, and affordability, meeting the needs of modern cabinetry with blazing speed and precision.

As Central Alabama's premier provider of TFL doors, we take pride in delivering products with realistic textures that rival the beauty of natural wood. Resistant to everyday wear and tear, our cabinet doors are a trusted choice for homeowners, designers, and cabinetmakers seeking quality and value.

We specialize in crafting premium Thermally Fused Laminate (TFL) cabinet doors. Our commitment to quality and innovation has established us as a leading manufacturer in the industry.

Our Mission

To provide exceptional quality TFL cabinet doors while maintaining superior customer service and competitive pricing.

Quality First

We use only the finest materials and latest manufacturing techniques to ensure our products meet the highest standards.

Customer Focus

Your satisfaction is our priority. We work closely with each client to ensure their needs are met.

Why Choose TFL Doors?

Durability

Our TFL doors are engineered to withstand daily wear and tear, maintaining their appearance for years.

Affordability

Get the look of real wood at a fraction of the cost, without compromising on quality.

Sustainability

Our manufacturing process is environmentally conscious, using sustainable materials and practices.

Design Versatility

Wide range of finishes from classic wood grains to modern metallics.

Why Choose Us?

Quality

We maintain rigorous quality control standards throughout our manufacturing process.

Experience

Our team brings years of expertise in cabinet door manufacturing.

Support

Our team is dedicated to exceptional service, offering expert guidance, quick responses, and reliable solutions.

Our Equipment

We use state-of-the-art machinery for precision cutting, edgebanding, and assembly. Check out our Equipment

Ready to Start Your Project?

Join the growing number of businesses and homeowners choosing TFL doors for their superior quality and design flexibility.

Our Door Styles

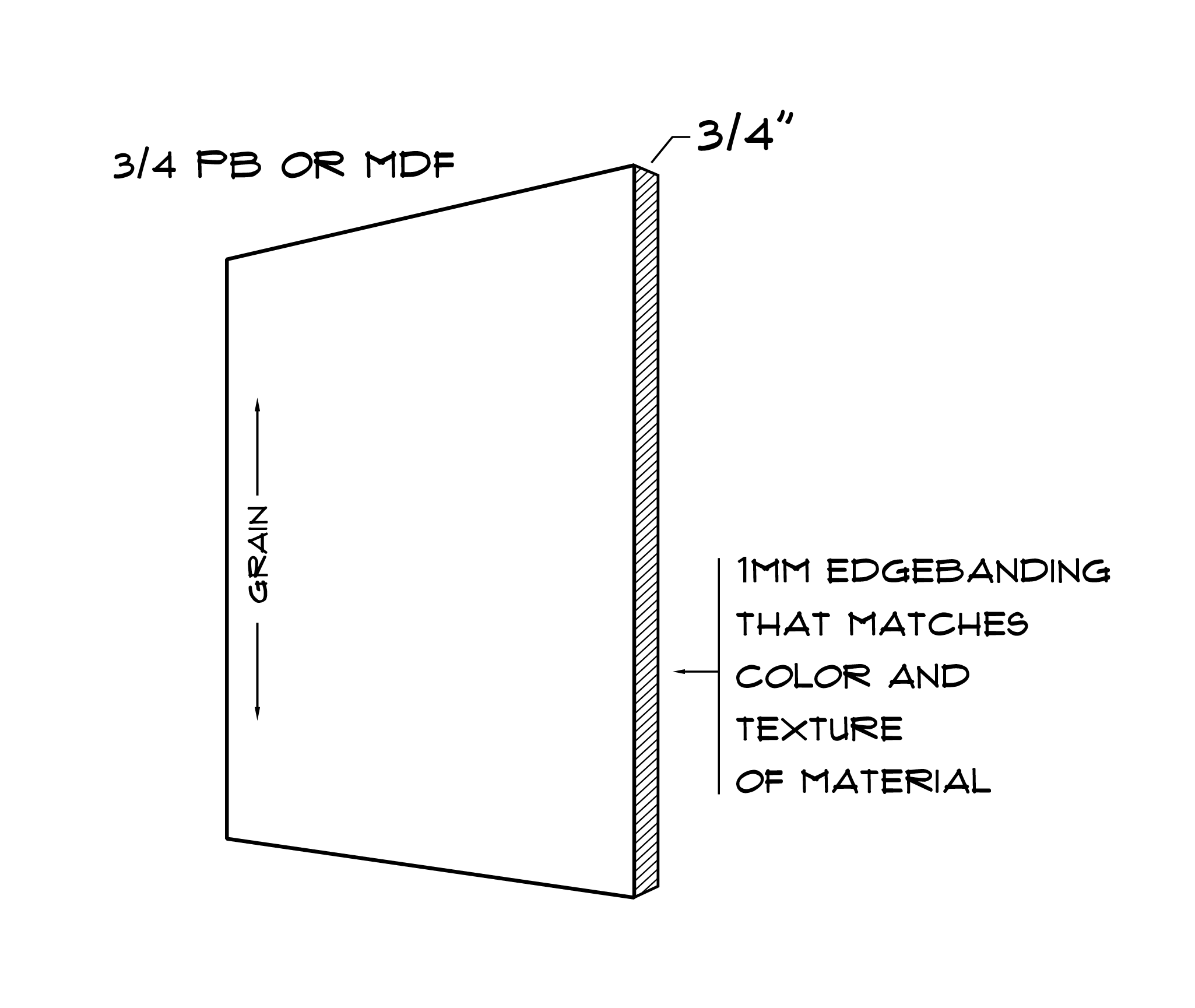

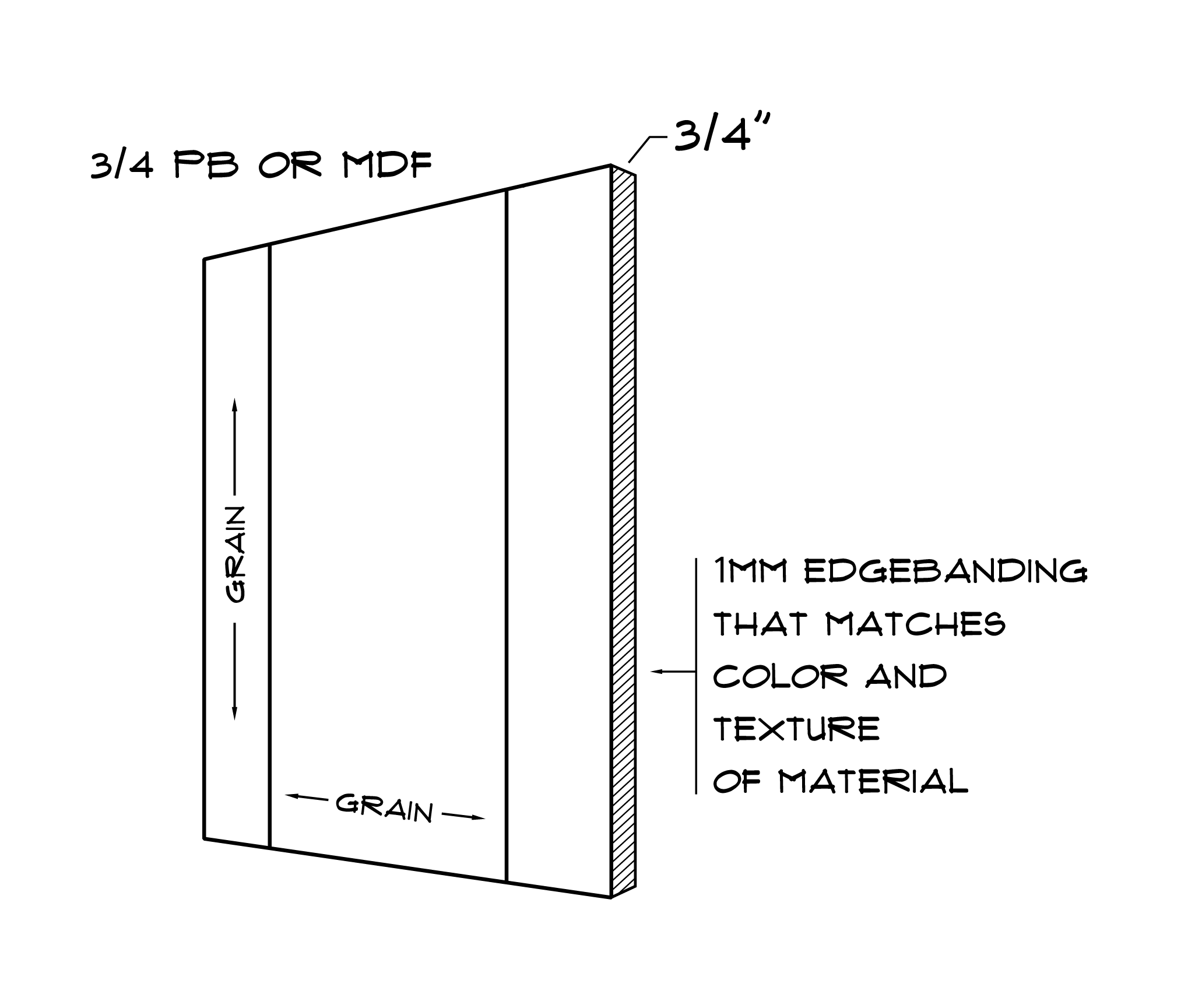

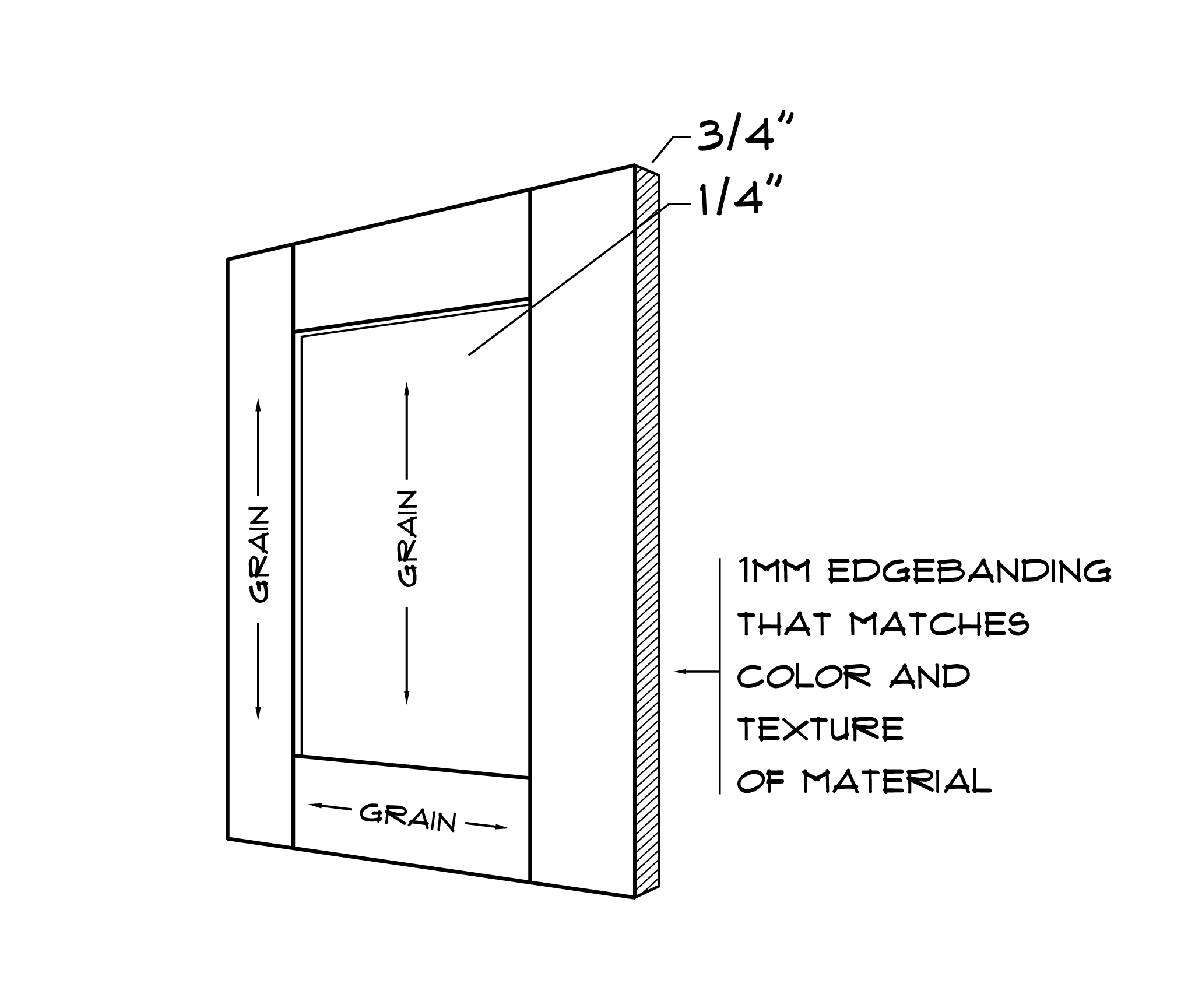

Materials

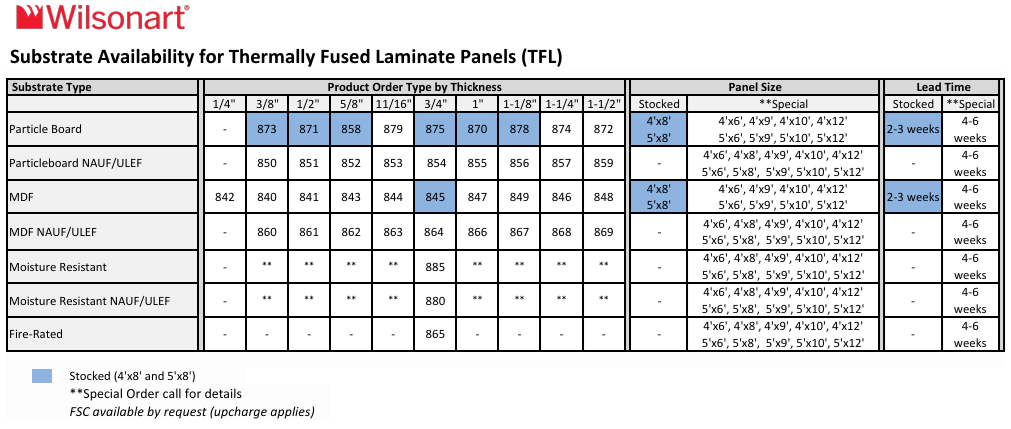

PB Thermally Fused Laminate

A versatile and economical choice that's lighter and easier to handle. Perfect for furniture, underlayment, and as substrate for HPL countertops.

MDF Thermally Fused Laminate

Premium medium-density fiberboard core used on the 5 Piece Cener panel

Available in MR-50 Moisture Resistant Substrate

Frequently Asked Questions

Thermally Fused Laminate (TFL) is created through a specialized, high-temperature, and high-pressure process that bonds a decorative surface to a substrate, resulting in a durable, hard-wearing finish. Here's an overview of how TFL is made:

Design & Paper Preparation:

- Printed Decorative Paper: The process starts with high-quality paper that's printed with the desired design or finish.

- Resin Impregnation: This paper is then impregnated with a melamine-formaldehyde resin, which is key to achieving the laminate's toughness and resistance to wear. After impregnation, the paper is thoroughly dried.

Substrate Preparation:

- A substrate material, typically medium-density fiberboard (MDF) or another engineered wood product, is prepared. This substrate provides structural support and stability to the final product.

Fusion Process:

- Assembly: The dried, resin-impregnated paper is carefully aligned on top of the substrate.

- High-Pressure, High-Temperature Pressing: The assembled layers are placed into a press where intense heat and pressure are applied. During this step, the resin melts and fuses the decorative paper directly to the substrate. This thermal bonding creates a seamless, robust surface that is both aesthetically pleasing and resistant to scratches, moisture, and heat.

Cooling and Finishing:

- Once the fusion process is complete, the laminate is cooled to set the resin, ensuring the bond is secure.

- Trimming and Inspection: The TFL is then trimmed to the desired dimensions and subjected to rigorous quality control checks before it is used in products such as doors.

This meticulous process ensures that TFL offers long-lasting durability and a high-quality finish, making it a popular choice for modern, stylish door designs at TFLdoor.com.

We also offer convenient local pickup at our facility. For those in a rush, a priority service is available at an additional charge to expedite your order.

At TFL Doors, we're dedicated to providing quality products and flexible solutions to meet your needs.

View Warranty Details

We understand that many cabinets have faceframes. Visit our Cabinet Recovery Program page to learn about our solutions for faceframe cabinets and how we can help transform your existing cabinets.

Yes! Visit our trim page to explore our TFL trim options and learn how they can complete your cabinet transformation.

A versatile and economical choice that's lighter and easier to handle. Perfect for furniture, underlayment, and as substrate for HPL countertops.

Medium-Density Fiberboard (MDF):

MDF is designed to be used as a substrate for decorative finishes such as melamine and laminate. Edges machine well for planing, drilling, and routing. Has longer screw holding in both face and edge than PB. Suitable for most joinery applications - interior cabinetry, wall and ceiling panels, and store fixtures.

Moisture Resistance (MR):

MDF MR is specially formulated to offer enhanced moisture resistance. MDF MR is designed to be used as a substrate for decorative finishes such as melamine and laminate. It is suitable for interior cabinetry, wall, and ceiling panels.

Fire-Rated (FR):

MDF FR is a medium-density fiberboard specifically manufactured to include flame retardants. This dramatically improves the fire resistance and spread of flame qualities compared with standard MDF and most other timber-based panel products. MDF FR is designed to be used as a substrate for decorative finishes such as melamine and laminate. It is suitable for interior cabinetry, wall, and ceiling panels.

Low VOC (NAF):

Environmentally friendly choice. No-Added Formaldehyde (NAF), CARB-compliant. Sustainable design.

Contact Us

Meet Our Team

Dave brings years of experience in the cabinet and door manufacturing industry. As the owner of TFL Door, he leads the company's strategic direction and ensures the highest standards of quality in all products and services.

His expertise in custom solutions and commitment to customer satisfaction has helped establish TFL Door as Central Alabama's premier provider of Thermally Fused Laminate doors.

Owner, Leadership & Vision

As Shop Foreman at TFL Door, Ryan oversees all aspects of production, ensuring each door meets our exacting quality standards. His expertise in manufacturing processes and team leadership keeps our production running smoothly and efficiently.

Ryan's dedication to precision and attention to detail helps maintain our reputation for delivering superior quality TFL doors to our customers.

Ryan

Shop Foreman, Production Management

As IT Director at TFL Door, Robert ensures our technology infrastructure runs smoothly and efficiently. His expertise in systems management and digital solutions helps streamline our operations and enhance customer service.

Robert's dedication to implementing cutting-edge technology solutions keeps TFL Door at the forefront of industry innovation.

Robert

IT Director, Technology & Systems

As our R&D specialist, Shea leads TFL Door's innovation initiatives, constantly exploring new designs and technologies to enhance our product offerings. His creative approach to problem-solving helps us stay ahead of industry trends.

Shea's expertise in design and innovation ensures that TFL Door continues to offer cutting-edge solutions that meet our customers' evolving needs.

Shea

Research and Development, Innovation & Design

Birmingham Door Works Lifetime Warranty for TFL Cabinet Doors

Manufacturing Defects

Our warranty covers any manufacturing defects that may occur during the production process. This includes issues with assembly, finish, or structural integrity.

Material Defects

We warrant that the materials used in our products will be free from defects and will perform as intended under normal use and conditions.

Delamination

Our warranty covers any delamination that may occur under normal use and conditions. This includes separation of materials or layers within the product.

Exclusions

The warranty does not cover damage caused by misuse, abuse, improper installation, or exposure to extreme conditions. Normal wear and tear are also not covered.

Alterations or Modifications

If the product has been altered, modified, or repaired by someone other than the manufacturer, the warranty will be void.